The forced circulation evaporator relies on external force-a forced circulation pump to circulate the liquid. The circulation speed can generally reach 1.0-3.5 m/s. The heat transfer efficiency and production capacity are large. The forced circulation evaporator is the material that is transported to the tubular heater through a large flow circulating pump, and then enters the separator for evaporation and separation after heating, and the unevaporated residual material is returned by the circulating pump again. The heater is heated to evaporate, thus forming a repeated circulation evaporation system, which is widely used in the evaporation and concentration of aqueous or organic phase solutions in food, medicine, chemical, environmental protection and other industries. It is especially suitable for materials with high viscosity, easy scaling and crystallization Intermittent or continuous evaporation concentration crystallization under normal pressure or vacuum conditions can be single-effect or multi-effect evaporation concentration crystallization.

2. Scope of application:

The forced circulation evaporator is suitable for the treatment of materials with scaling, crystallinity, heat sensitivity (low temperature), high concentration, high viscosity, and insoluble solids with particles. It is a variety of fruit pulp (tomato sauce), corn soaking Ideal equipment for the concentration of heat sensitive materials such as water, inorganic salts (ammonium sulfate, sodium chloride, etc.), malt extract, starch sugar, glucose, Vc, lysine, oligosaccharides, inositol, protein peptides, etc.

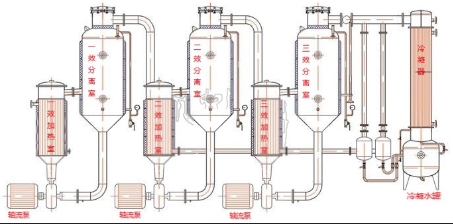

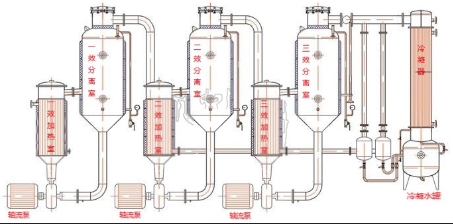

3. System composition:

Each effect evaporator, each effect separator, condenser, circulating pump, transfer pump, vacuum and drainage system, operating platform, electrical instrument control cabinet and valves, pipelines and other systems.

4. Equipment features:

1. The complete system has reasonable and beautiful design, stable operation, high efficiency and energy saving, and low steam consumption;

2. Large concentration ratio and forced circulation make it easy to flow and evaporate the material liquid with higher viscosity;

3. The special design can realize the switching effect after simple operation to adapt to the production of different products;

4. The evaporation temperature is low, the heat is fully utilized, and the material liquid is heated gently, which is suitable for the concentration of low-temperature heat-sensitive materials;

5. The evaporator is heated evenly in the tube through forced circulation, and the heat transfer coefficient is high, which can prevent the dry wall phenomenon;

6. The material and liquid enter the separator and separate again, which strengthens the separation effect and makes the overall equipment more flexible in operation;

7. The whole set of equipment has compact structure, small floor space, simple and smooth layout, and easy to clean;

8. Continuous feeding and discharging, the liquid level and concentration of the material can be controlled automatically;

5. Technical parameters:

|

Model

|

CZQX-01

|

CZQX-02

|

CZQX-03

|

CZQX-04

|

|

Water Evaporation capacity

|

0.5-5

|

0.5-10

|

2-30

|

5-30

|

|

Input concentration

|

(According to material)

|

|

Output concentration

|

(According to material)

|

|

Steam pressure(Mpa)

|

0.2-0.4

|

|

Maximum Vacuum(mmhg)

|

650

|

|

Evaporation temperature(℃)

|

45-90

|

|

Steam consumption/Evaporation capacity(kg/kg)

|

1.2

|

0.65

|

0.40

|

0.37

|

|

Cooling water cost/Evaporation capacity(T/T)

|

32

|

16

|

11

|

9

|

|

Note:We can design and manufacture according to customers special requirement.

|

6. Process flow: