PRODUCTS

HEBEICHENGZEHUAGONGSHEBEICO.,LTD

Falling film evaporator

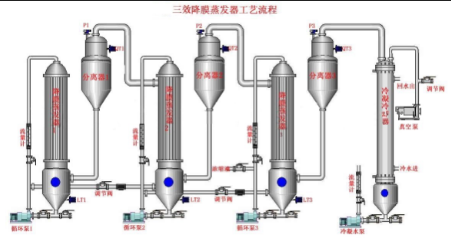

Falling film evaporation is to add the material liquid from the upper tube box of the heating chamber of the falling film evaporator, and distribute it evenly into the heat exchange tubes through the liquid distribution and film forming device. It can be single-effect or multi-effect evaporation and concentration.

|

specification |

Distilled water(Kg/h) |

Total heat transfer area(㎡) |

Tube length(m) |

Effective number |

Steam consumption(t/t) |

Total power(KW) |

|

CZJMR05-28 |

28000 |

1674 |

9 |

5 |

0.135-0.17 |

27.5 |

|

CZJMR05-22 |

22000 |

1349 |

9 |

5 |

0.136-0.17 |

24.5 |

|

CZJM05-30 |

30000 |

1160 |

9 |

5 |

0.27 |

20 |

|

CZJM05-22 |

22000 |

730 |

6 |

5 |

0.275 |

19 |

|

CZJMR04-20 |

20000 |

1136 |

9 |

4 |

0.17-0.19 |

17.5 |

|

CZJMR04-15 |

15000 |

700 |

8 |

4 |

0.17-0.19 |

8.8 |

|

CZJMR04-8 |

8000 |

360 |

6 |

4 |

0.18-0.2 |

6.6 |

|

CZJM04-15 |

15000 |

420 |

9 |

4 |

0.3-0.31 |

6 |

|

CZJM04-8 |

8000 |

220 |

6 |

4 |

0.3-0.31 |

4.5 |

|

CZJMR03-7 |

7000 |

265 |

6 |

4 |

0.29-0.32 |

13.5 |

|

CZJM03-13 |

13000 |

478 |

6 |

3 |

0.29-0.31 |

3.7 |

|

CZJM03-10 |

10000 |

197 |

6 |

3 |

0.4-0.42 |

2.2 |

|

CZJM03-7 |

7000 |

130 |

6 |

3 |

0.4-0.42 |

4.4 |

|

CZJMR02-3.5 |

3500 |

91 |

4.5 |

2 |

0.38-0.42 |

9.5 |

|

CZJMR02-10 |

10000 |

274 |

6 |

2 |

0.38-0.41 |

2.7 |

|

CZJM02-2 |

2000 |

58 |

3 |

2 |

0.4-0.42 |

1.1 |

|

CZJM02-3.5 |

3500 |

80 |

4.5 |

2 |

0.57-0.6 |

2.2 |

|

CZJM02-10 |

10000 |

175 |

6 |

2 |

0.57-0.6 |

4.4 |

|

CZJM02-2 |

2000 |

46 |

3 |

2 |

0.57-0.6 |

2.2 |

|

CZJM02-5 |

5000 |

114 |

6 |

2 |

0.57-0.6 |

3 |

|

CZJMR01-1 |

1000 |

25 |

3 |

1 |

1.1-1.15 |

13 |

|

CZJM01-1 |

1000 |

20 |

3 |

1 |

1.1-1.15 |

3 |

Product message

CONTACT US

E-mail: sales@hbhgsb.cn

Tel: +86-311-83756555 / 83951911

Wechat: 18031837273

Fax: +86-311-85837070

Copyright 2020 Hebei Chengze Chemical Equipment Co., Ltd 冀ICP备18023413号-1 Powered by www.300.cn