Disc continuous dryer is a highly efficient conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely used in chemicals, medicine, pesticides, food, feed, and agriculture. Drying operations in industries such as by-product processing. It is well received by users in the practice of various industries. Now our company produces three types of atmospheric pressure, airtight, vacuum, 1200, 1500, 2200, 3000 four types, A (carbon steel), B (stainless steel in contact with materials), C (on the basis of B, increase The steam pipeline, main shaft and bracket are made of stainless steel, and the cylinder and cover are lined with stainless steel). Three kinds of materials, a drying area of 4~180m 2, a total of hundreds of models of series products, and can provide a variety of auxiliary equipment to meet the needs of users for drying various materials.

The disc dryer is a multi-layer hollow disc structure, and the wet material is continuously added to the first drying disc on the upper part of the dryer, and the rake arm with the rake leaves rotates so that the rake leaves continuously turn over the material. The material flows through the surface of the drying plate along an exponential spiral, and falls to the drying plate below one by one. The large and small drying trays are arranged alternately up and down, so that the material can continuously flow through the entire dryer. A heating medium such as saturated steam, hot water, heat transfer oil or high-temperature molten salt is passed into the hollow drying plate. Dried materials fall from the bottom layer of the drying plate to the bottom layer of the shell, and are finally moved by the rake leaves to the discharge port for discharge. The moisture overflows from the material and is discharged through the moisture discharge port on the top cover. The moisture of the vacuum disc dryer is discharged from the vacuum pump port on the top cover. The solvent can be easily recovered by adding a condenser. Adding auxiliary equipment such as fin heater, bag filter, induced draft fan, etc. can improve its drying production capacity. The tray dryer can also perform pyrolysis and reaction operations.

Features

1. Easy to control, strong applicability, and very simple to start and stop operations.

2. Each layer of drying tray can be fed with hot/cold medium separately, and the material temperature can be controlled accurately.

3. The residence time of the material can be adjusted accurately.

4. Single material flow direction, no back-mixing phenomenon, uniform drying and stable quality.

5. After stopping the feeding, the rake blades that convey the material can quickly empty the material in the dryer.

6. Through the special large-size inspection door and sight glass, the inside of the equipment can be carefully cleaned and observed.

7. The material layer is very thin, the spindle speed is low, the system installed power is small, and the power consumption is low.

8. The operating environment is good, the solvent can be recycled, and the exhaust dust content is very low.

9. It can be operated under vacuum, especially suitable for drying heat sensitive materials.

10. The dryer is delivered as a whole, and only needs to be hoisted in place, which is very easy to install and locate.

11. Drying trays are arranged in layers and installed vertically, occupying a small area.

Operating procedures

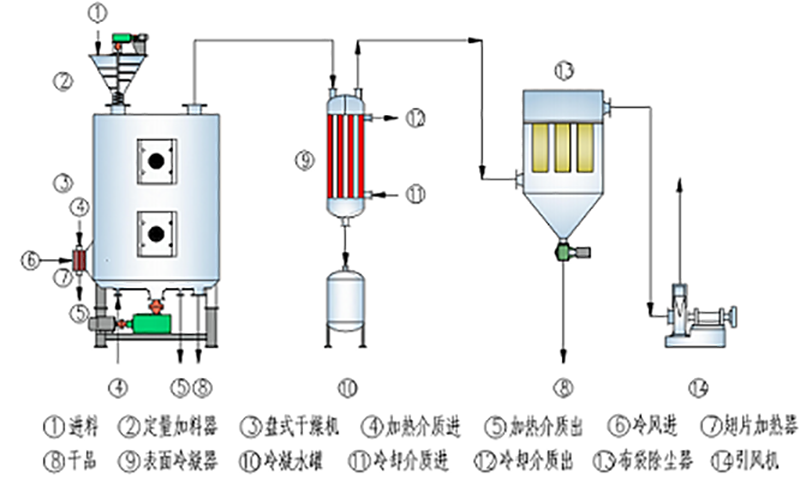

Basic configuration disc continuous drying process

The wet material is uniformly added to the top of the disc continuous dryer through a quantitative feeder, and the drying process is completed when flowing through the dryer from top to bottom, and the dry material is discharged from the bottom of the dryer. The moisture escaping from the material is discharged into the atmosphere through the moisture outlet on the top of the dryer.

Optional disc continuous drying process

On the basis of the basic configuration, according to the different drying requirements of different materials, some auxiliary settings can be added to achieve a better drying effect:

| Optional equipment |

Function Description |

| Fin heater |

It is suitable for the drying process with high evaporation intensity. A small amount of hot air is passed into the dryer to absorb the moisture overflowed from the material during the drying process, which can prevent moisture condensation on the top of the dryer and the exhaust cylinder. |

| Induced draft fan |

Introduce a larger amount of air to strengthen the heat transfer and drying process to quickly absorb the moisture overflowed during the drying process and prevent moisture condensation on the top of the dryer and the exhaust tube |

| dust collector |

Improve the operating environment, and capture the small, particularly fine and light materials entrained in the exhaust gas to protect the environment and reduce product losses. Bag dust collectors or wet dust collectors can be selected. |

| Surface condenser |

Condensate and recover valuable condensable solvents overflowing from the drying process |

| Solvent receiving tank |

Condensate solvent receiving tank |

Scope of application

Organic chemical products

Polyvinyl chloride resin, polytetrafluoroethylene resin, glycine, fumaric acid, anthraquinone, nitroanthraquinone, p-aminophenol, melamine, cyanuric acid, p-aminobenzene sulfonic acid, antioxidant 168, chromophenol As , Stearate, aniline, nitroaniline, dipentaerythritol, chlorinated paraffin, calcium formate, triethylenediamine, EDTA, rubber accelerator, sodium benzenesulfinate, dimethyl isophthalate-5-sulfonate Sodium, thiourea, oil-soluble nigrosine dyes, acid black dyes, indigo, pearlescent pigments, etc.

Inorganic Chemical Products

Light calcium carbonate, activated calcium carbonate, nano calcium carbonate, magnesium carbonate, pyrite concentrate, pyrite, copper-nickel ore, aluminum hydroxide, white gray black, strontium carbonate, barium carbonate, potassium carbonate, lithopone, sodium hydroxide , Silica powder, barium sulfate, potassium sulfate, microsphere catalyst, magnesium hydroxide, copper sulfate, nickel sulfate, nickel acid amine, sodium molybdate, sodium chloride, cryolite, iron oxide red, iron oxide black, iron oxide yellow , Nickel oxalate, cobalt oxalate, lithium hydroxide, lithium carbonate, lithium chloride, nickel hydroxide, cobalt hydroxide, cobalt carbonate, nickel cobalt manganese ternary precursor, cobalt tetroxide, zirconium hydroxide, calcium phosphate, sulfur, etc.

Medicine, food

Ampicillin, Deng's salt, L-phenylglycine and intermediates, cefotaxime, ceftriaxone, methamphetamine, cimetidine, vitamin B12, vitamin C, medicinal salt, medicinal aluminum hydroxide, medicinal partial Magnesium silicate, caffeine, tea, flower extract, ginkgo biloba, chocolate powder, starch, corn germ and other raw materials and pharmaceutical intermediates.

Feed, fertilizer

Potassium carbonate, biological potash fertilizer, protein feed, chlortetracycline for feed, mycelium, bran, distiller's grains, grain, seeds, herbicide, cellulose, etc.

Specification, model

|

规格

|

Outer diameter(mm)

|

height(mm)

|

Dry area(㎡)

|

power(kW)

|

specification

|

Outer diameter(mm)

|

height(mm)

|

Dry area(㎡)

|

power(kW)

|

|

CZPG1200/4

|

1850

|

2718

|

3.3

|

1.1

|

CZPG2500/6

|

3150

|

3319

|

24.8

|

4.0

|

|

CZPG1200/6

|

3138

|

4.9

|

CZPG2500/8

|

3739

|

35

|

|

CZPG1200/8

|

3558

|

6.6

|

1.5

|

CZPG2500/10

|

4159

|

43.8

|

5.5

|

|

CZPG1200/10

|

3978

|

8.2

|

CZPG2500/12

|

4579

|

52.5

|

|

CZPG1200/12

|

4398

|

9.9

|

2.2

|

CZPG2500/14

|

4999

|

61.3

|

7.5

|

|

CZPG1500/6

|

2100

|

3022

|

8.0

|

CZPG2500/16

|

5419

|

70

|

|

CZPG1500/8

|

3442

|

10.7

|

CZPG2500/18

|

5839

|

78.8

|

11

|

|

CZPG1500/10

|

3862

|

13.4

|

CZPG2500/20

|

6259

|

87.5

|

|

CZPG1500/12

|

4282

|

16.1

|

3.0

|

CZPG2500/22

|

6679

|

96.3

|

|

CZPG1500/14

|

4702

|

18.8

|

CZPG2500/24

|

7099

|

105

|

15

|

|

CZPG1500/16

|

5122

|

21.5

|

CZPG2500/26

|

7519

|

113.8

|

|

CZPG2200/6

|

2900

|

3319

|

18.5

|

CZPG3000/8

|

3800

|

4050

|

48

|

11

|

|

CZPG2200/8

|

3739

|

24.6

|

CZPG3000/10

|

4650

|

60

|

|

CZPG2200/10

|

4159

|

30.8

|

4.0

|

CZPG3000/12

|

5250

|

72

|

|

CZPG2200/12

|

4579

|

36.9

|

CZPG3000/14

|

5850

|

84

|

|

CZPG2200/14

|

4999

|

43.1

|

5.5

|

CZPG3000/16

|

6450

|

96

|

|

CZPG2200/16

|

5419

|

49.3

|

CZPG3000/18

|

7050

|

108

|

15

|

|

CZPG2200/18

|

5839

|

55.4

|

7.5

|

CZPG3000/20

|

7650

|

120

|

|

CZPG2200/20

|

6259

|

61.6

|

CZPG3000/22

|

8250

|

132

|

|

CZPG2200/22

|

6679

|

67.7

|

11

|

CZPG3000/24

|

8850

|

144

|

|

CZPG2200/24

|

7099

|

73.9

|

CZPG3000/26

|

9450

|

156

|

18.5

|

|

CZPG2200/26

|

7519

|

80.0

|

CZPG3000/28

|

10050

|

168

|